Description

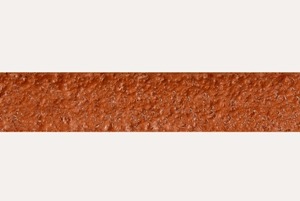

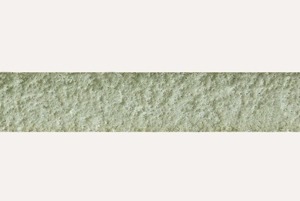

SILER – 3

CEMENT AND POLYMER-BASED POLYMER FINISHING PLASTER

Plaster comes in two main colours – grey and white. UNINAKS plaster tinted with mineral pigments (see the colour chart) can be manufactured based on orders.

USAGE

As a spray plaster for applying onto walls with a plastering machine.

For manual plastering with steel trowels.

For internal and external plastering works. For dry, damp and wet conditions.

SUBSTRATES

For substrates made of concrete, lightweight concrete, masonry, already plastered surfaces and other mineral surfaces suitable for plastering.

Siler-3 is a spray plaster ideal to be used as a finishing plaster in the UniTherm insulating system.

The substrate shall be clean, strong enough and dust-free. Substances, such as loose paint, grease, dust and non-moisture resistant levelling courses reducing bondage with the substrate shall be removed.

PREPARATIONS

Add clean lukewarm water as approx. 17-22% of the weight of the mixture (4.25-5.5 l per 25 kg package).

Add the necessary quantity of dry mix.

Mix carefully with a mixer until the mixture is completely wet.

Wait for a couple of minutes and mix moderately once again.

Ready-made plaster should be used within 4 hours.

APPLYING

Very dry and porous surfaces should be previously moistened.

Treat weak substrates with Uninaks DEEP IMPREGNATING PLASTER.

When using a plastering machine cover all door and window openings and other surfaces that should not get plastered with a suitable material. Use a plastering machine with appropriate power and a suitable nozzle. Conduct test plastering before starting to cover public surfaces.

Best results are achieved when applying two layers on surfaces. Before applying the second layer, let the first layer dry for at least one day.

When manually applying use steel trowels.

The thickness of one plaster layer should normally be 4-8 mm, in case of partial plastering up to 1 cm.

CURING

The curing time of one plaster layer depends on the layer thickness, moisture content and temperature of the environment.

Before applying the next plaster layer let the previously applied layer dry for at least one day.

In extremely dry conditions we recommend moistening already plastered surfaces before new plastering and within 2-3 days after plastering. Cured surfaces are excellent for covering with paints suitable for mineral surfaces.

LIMITATIONS

Substrate, plaster and ambient temperature during application process and a day after it shall exceed +5° C.

Freshly plastered surfaces shall be protected from direct sun and rain exposure.

The product contains cement. Contact with water causes an alkaline reaction. Can cause skin irritation. Upon contact with eyes rinse immediately with plenty of water.

For more specific information please refer to the Safety Data Sheet.

CONSUMPTION

App. 6-7 kg of mix powder per plastering 1 m2 with a 5 mm thick plaster layer.

STORAGE

Shelf life in original package and in dry storage conditions is up to one year.