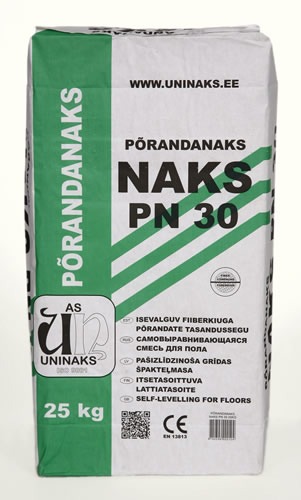

Description

NAKS + P

Self-levelling and fast hardening floor levelling mix for problematic substrares.

Can be used on wood and for making floating floors.

USAGE

Self-levelling, fast hardening floor levelling mix with persistent volume. To be applied manually or with a pump.

Also suitable to be applied in a thicker layer and for making floating floors.

USAGE

Used for levelling floors made of concrete, stones, wood, water resistant veneer, gypsum lathe, etc.

Can be used for covering underfloor heating systems.

Used as a substrate for parquet, coverings, glazed tiles, carpets, etc.

For internal use only. To be used in conditions with no permanent exposure to water.

COMPOSITION

Special cements, sand, additional additives and fillers, polymers, plasticisers and fibres.

PROPERTIES OF THE PRODUCT

Flow properties of the ready mix are 140-150 mm pursuant to EN 12706.

Tensile strength of the hardened mix is over 1 MPa and the minimum compressive strength is 30 MPa.

MIX PREPARATION

Add lukewarm water 20-22% of the weight of the mix. 5–5.5 litres per 25 kg bag.

Mix carefully until the mixture is completely wet. Wait for a couple of minutes and stir once again.

Check that the mixture is completely homogeneous. Ready mixture to be used within 15-20 minutes after adding water.

APPLICATION

Clean the floor surface of loose particles and dust. If needed, use a vacuum cleaner.

Treat the subfloor with Adhesive Dispersion and leave drying for a couple of hours (touch-dry).

Mixture can be poured or pumped out with a mixer pump.

If necessary use a spiked roller or a levelling lute to aid levelling.

Thickness of the levelling compound shall be between 3-50 mm.

CURING

The floor is foot traffic-resistant within 2-3 hours. Final floor can be laid in 7 days.

Curing time depends on the layer thickness, room temperature and moisture content.

COVERAGE

1.7 kg/m2 of mix powder per mm/layer.

8.5 kg/m2 per 5 mm/layer.

LIMITATIONS – WARNINGS – TIPS

Mixture to be used in ambient temperature from + 10 0C to + 35 0C.

Levelling compound should not be used on surfaces containing oil, grease or light fuel oil.

Curing process shall not be accelerated with heating the floor or ventilating the room.

Avoid direct exposure of sunshine on freshly laid floor.

The product contains cement. Contact with water causes alkaline reaction. Can cause skin irritation.

Upon contact with eyes rinse immediately with plenty of water. For more specific information please refer to the Safety Data Sheet.

STORAGE

Shelf life in original package and dry storage conditions is up to 6 months. Production date on the package.